Facilities

Departmental facilities

The Department of Aeronautics has excellent facilities for research and teaching.

Our facilities support computational and experimental projects in fluid mechanics, structural analysis, composites, optimisation and control and aircraft design.

Experimental research is supported by well-appointed laboratories and wind tunnels, and some of the equipment hosted here is unique to the UK.

Enquiries about the use of facilities may be directed either to the Department Operations Manager Siân Haynes, the Wind Tunnel Manager, Dr Nigel MacCarthy or by contacting the relevant facility manager, listed under each facility.

Facilities

2nd block of 3

Departmental facilities available for commercial testing

Computing resources

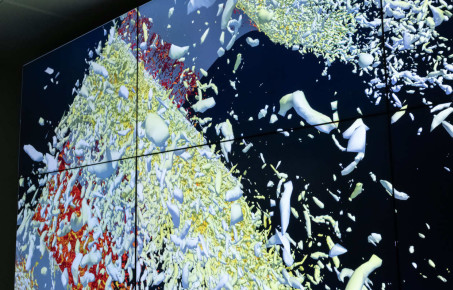

Given the highly computational nature of the department, it is not surprising that computing facilities are outstanding. Research activities make use of two High Performance Beowulf clusters, an Itanium server and a large number of Linux and Unix workstations, as well as Windows PCs. In addition, research groups have access to College-wide and external parallel facilities.

There are two teaching laboratories open to all department members. The main teaching laboratory consists of 44 HP PCs running Linux and Windows. The second teaching cluster has 28 computers, 18 of which are dual-boot and 10 are Linux-only PCs used mainly for projects. Both computer rooms operate between the hours of 7.00 and 22.00, seven days a week.

The two clusters and all the research workstations are linked via 100Mbit links to the 1Gbit College network and the Internet.

Peripherals available for public use include several high-resolution laser printers, including a colour laser printer.

Undergraduates make extensive use of the computer laboratories for classes such as an in-depth programming course, numerical methods courses and Computer-Aided Design courses using a three-dimensional solid modeller package. In addition, it is used for projects which range from Finite Element analysis to Aircraft Design and Computational Fluid Dynamics.

Computing information: Dr Omar Bacarreza Nogales

Flight simulator

Full-motion flight simulator

The Department of Aeronautics has its own full-motion flight simulator. This is a highly re-configurable simulator that can be programmed to accurately simulate almost any type of aircraft. It is equipped with a two-seat cockpit with fully programmable glass display instrument panels, realistic dual side-by-side flight controls, systems switches, full radio navigation stack, replaceable multi-engine throttle quadrants and a full autopilot. A 140-degree wrap-around external visual system provides a realistic representation of the surrounding terrain, major topographical landmarks and accurate airport runway layouts for all the airports around the world.

The system is also provided with a full aeronautical navigation database and a day/night weather generation capability. The cockpit is mounted on to a six-degree of freedom all-electric full-motion platform which significantly enhances the flight simulation realism. An instructor operating station is also available, equipped with controls and displays for setting up different flight scenarios, changing the weather, inducing aircraft system malfunctions, and for flight monitoring in general. The flight simulation is controlled by six computers.

For further information please contact Dr Errikos Levis

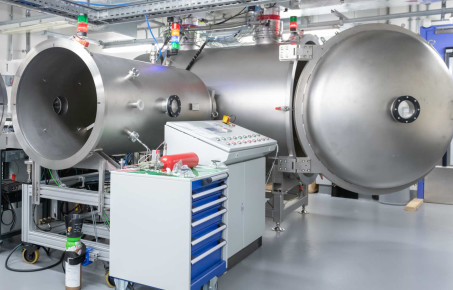

Wind tunnels

The Department has a comprehensive series of wind tunnels, covering speeds from a few metres per second to Mach 9. There are 5 general purpose low-speed tunnels with working sections from 0.4 to 16 square metres.

The complete list of facilities is as follows:

The 10x5 low-speed wind tunnel

This tunnel has two large test sections and the lower section is fitted with a moving floor and is used extensively for F1 racing car and saloon car testing. It is also fitted with equipment to simulate the atmospheric Boundary Layer for wind engineering of buildings and other structures (1:200 scale and upwards).

This facility is part of the National Wind Tunnel Facility and is capable of road vehicle and racing car aerodynamic testing. The lower test section is 3m x 1.5m x 20m long and the upper section 5.7m x 2.8m x 18m long. Wind shear and turbulence of the atmospheric environment can be simulated in this for studies of pollution and the wind loading of buildings and structures. The tunnel has a sophisticated 3-axis probe traversing mechanism, non-intrusive particle image velocimetry (PIV) equipment and the control and data processing are fully computerised. For more information contact the wind tunnel manager below and visit the 10x5 wind tunnel section.

The T2 low-speed wind tunnel

This tunnel is temperature regulated and fitted with a 3-axis precision traverse. The following are its main characteristics:

- 1.6m x 1.1m cross-section (4m length)

- 40m/s air speed

- 3-axis traverse mechanism

- Computer control

- Temperature regulated

Other wind tunnels

There are also six wind tunnels ranging in capability and test section size with speeds of up to Mach 9. These are:

- Low-speed T1 wind tunnel, top speed 40 m/s, with 0.91m-square x 5m long working section and 3-axis precision traverse. The flow in this tunnel has a very low turbulence level.

- 18" Closed-circuit wind tunnel with a 55m/s top speed and a 0.45m square test section which is 2m long

- Supersonic wind tunnel 0.15m x 0.15m cross-sectional area capable of up to Mach 5 flows for 30 secs duration

- Hypersonic gun tunnel. This is a short duration facility with a nozzle exit diameter of 0.34m. It operates at Mach 9 and achieves unit Reynolds Numbers in excess of 40 million; it is thus suitable for the study of transition and turbulent boundary layer flows.

- 18" Open Jet wind tunnel with Centrifugal fan, precision AC drive system and traverse. Speeds up to 30 m/s.

- 10" FloTek open jet wind tunnel for system preparation, probe calibration etc.

We also have various blower wind tunnels of varying cross-sectional area for small scale aerodynamic experiments.

Wind tunnel manager: Dr Nigel MacCarthy

WATER EQUIPMENT

The Department has a facility that uses water as the working medium and has been developed especially to study the wave forces on sea-based structures:

- A 9m long water channel with 0.6m-square section and computerised towing carriage. This flow channel is particularly useful for flow visualisation.

For information contact: Dr Nigel MacCarthy

Composites

The Department is host to many facilities used in the manufacture, characterisation and mechanical testing of composites.

Structural testing

The Department has a long tradition of testing complex mechanical and structural components. Testing of materials, compression and tension, fatigue, environment, high energy and gravitational impacts, is available.

Most of the equipment is fitted with electronic instrumentation and/or is computer controlled.

Testing Equipment

- New 250kN Instron (9585) test machine with environment chamber -150/+350 Centigrade. Hydraulic Grips with 320kN grip capacity

- Two new 50kN Instron (5969) test machines

- New 250kN Instron 8802 hydraulic test machine with environment chamber -150/+350 centigrade. Water cooled hydraulic crisps for use in the environment chamber

- Instron 100kN hydraulic fatigue machine with hydraulic grips

- Instron 25kN high rate hydraulic test machine up to 3m/s with hydraulic grips

- New 10kN Instron ElectroPuls E10000 together with 100Nm torque capability

- New Instron 1800 Joule drop tower (Ceast 9350) with environment chamber -70/+150 Centigrade

- Custom build compression frame to pre-load panels up to 1m wide and 1.5 m long with up to 150 tonnes pre-load prior to impact

- TA Instruments RSA-G2 DMTA machine with an environment chamber to -150/+500 Centigrade

- Custom built 250 tonne hyper stiff compression machine

- Custom build gas gun 50mm bore up to 1200m/s

- Custom built gas gun 25mm bore up to 500m/s

- Latest Aramis 3D Digital Image Correlation system giving full field strain and out of plane buckling

- Latest Mistras Acoustic Emission system for detecting fibre and matrix failures

- Phantom V2511 High Speed Camera

- Two Phantom V12.1 High Speed Cameras

- Two Imetrum Optical Strain systems

- Clip on Extensometers

- Strain gauge measurement capacity on all machines

- All test machines have fixtures and fittings to meet most test standards

- Fully equipped workshop to manufacture custom fittings

Structural testing information: Mr Joseph Meggyesi

Aerial robotics

Vicon Flight ArenaFlight Arena

A large enclosed 10x6.2x5.5m flight arena, equipped with 16 Vicon T40 tracking cameras, capable of tracking multiple flying objects in 6 degrees of freedom, with millimetre accuracy. Tracking data can be used for closed loop control of vehicles.

Microthruster Lab

Flight test lab with full fume extraction (air replaced 15 times/hour),DPSS laser allowing for the safe indoor testing of combustible fuels and rocket engines for micro aerial vehicles. The lab is equipped with a 8-camera Optitrack system for vehicle tracking, a water tank for aerial-aquatic tests, and a protected observation area.

Laser Micromachining System

A diode-pumped solid state laser capable of machining 3-dimensional structures into almost any material, with a beam diameter of 8µm at maximum focus.

Objet 350 Connex Rapid Prototyping Machine

A multi-material 3D printing system, with a 350x350x200mm build envelope and a 16µm layer height. The machine is capable of printing rigid mechanisms as well as in soft rubber-like materials.

SCS Labcoater Parylene Deposition System

A parylene deposition system capable of manufacturing microscale flexible skins, and conformal coatings for the protection of components hondaturbines from water damage and solvents.

Imperial College Composites Centre

An interdepartmental centre, with experience in design and fabrication of the whole spectrum of modern composite materials.

Wind Tunnels

The Aeronautics department has a comprehensive series of wind tunnels, covering speeds from a few metres per second to Mach 9. There are 5 general purpose low speed tunnels with working sections from 0.4 to 4.5 square metres.

Unmanned Aerial Vehicles

A huge range of testing platforms, ranging from heavy lift (>5kg) octocopters, to high precision conventional quadrotors and high performance micro (<100 gram) vehicles. These vehicles are used to test novel mechansims and flight algorithms, or are modified to operate reliably in realistic environments.

Thermoforming Equipmentco2laser

Vacuum forming and strip heating machines for the manufacture of plastic shell structures.

FDM Rapid Protyping Systems

Makerbot 5 and Stratasys Dimension 3D printers for rapid manufacture of components in ABS and PLA plastics.

CO2 Laser Cutter

Laser rapid prototyping system capable of rapidly producing 2-dimensional structures in a wide variety of plastics and wood materials.