Applications

|

|

|

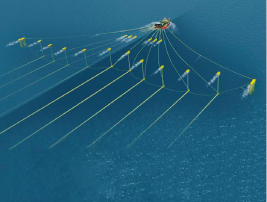

Seismic Towing

|

|

Towing Ropes

Superline or D12 Plus (with or without cover)

Separation Ropes

D12 Plus

Winch Lines

Superline, D12 Plus, Dynaline

Bridle Assemblies

D12 Plus

|

Benefits of UHMPE ropes in seismic surveying:

- Easier handling compared to steel

Drag reduction in the water through lower diameter

& equal strength

- More accurate positioning of the sensors due to low elongation

- Elimination of the “catenary” effect due to UHMPE

positive buoyancy

-

Extended lifespan, due to tension and bending

fatigue resistance

- No snap back issues / recoil in event of failure

-

Industry reports show that towing lines made with

UHMPE require replacement only every two years. Steel

wire ropes used in seismic applications typically have

a lifetime of 4-5 months.

- All ropes available with fairings for elimination of

turbulence and vortex induced vibration

|

|

|

|

Traction Winches

|

|

|

|

Oceanus

12 strand UHMPE core construction with UHMPE and Para-Aramid blended cover.

Benefits of Oceanus UHMPE rope on traction winches:

- Specialist GripCoat technology bonds core and core preventing cover slip GripCoat bonding ensures effective transfer of force between core and cover

- Use of Dyneema XBO significantly reduces bend fatigue and increases service life under extreme bending conditions

- Blended UHMPE / Para-Aramid cover ensures excellent cut and abrasion resistance whilst maintaining a high coefficient of friction and heat resistance.

- Manufactured to specific lengths including factory splices with machine finish

D12 Plus 12 strand UHMPE with GripCoat or ICO DYN 10

Benefits of D12 UHMPE rope on traction winches:

- Open 12 strand construction aids inspection and reduces heat build up.

- GripCoat ensures effective transfer of force between winch and rope

- Use of Dyneema XBO significantly reduces bend fatigue and increases service life under extreme bending conditions

- Manufactured to specific lengths including factory splices if required

|

|

|

|

Escort & Ocean Towing

|

|

|

|

D12 Plus

12-strand construction offers high strength and excellent abrasion resistance. Nylon springs can be spliced into the assembly for improved elasticity.

Superline

Multiple 3-strand load-bearing cores with a polyester or blended cover. Excellent for use on winches offering firm round construction and excellent abrasion resistance.

|

Benefits of UHMPE ropes in towing applications:

- High strength – meets the increasing demands of today’s towing environment

- Light weight – easily handled, increasing ease and speed of connection to towed vessel

- Positive buoyancy – rope floats meaning easy transfer in emergency situations

- Increased safety – very low extension and consequently limited / no recoil on failure

|

|

|

|

Mooring

|

|

|

|

D12 Plus

Soft and flexible for easy handling and stowage. Nylon springs can be spliced into the assembly for improved elasticity.

D12 Plus with cover for use with deck mooring winches

Compact and round with good grip and abrasion resistance.

|

Superline

Multiple 3-strand load-bearing cores with a polyester or blended cover. Excellent for use on winches offering firm round construction and excellent abrasion resistance.

Benefits of UHMPE ropes in towing applications:

- Superior strength and low extension

- Lightweight, meaning easy handling and quick deployment when compared with traditional Polyolefin, nylon, polyester or wire.

- Mooring can be quick and secure with minimum personnel

|

|