- published: 20 Jun 2011

- views: 1325847

-

remove the playlistFiber Optic

- remove the playlistFiber Optic

- published: 22 Feb 2015

- views: 18898

- published: 15 Jul 2011

- views: 257794

- published: 07 May 2009

- views: 405775

- published: 16 Feb 2012

- views: 123689

- published: 15 Apr 2015

- views: 11257

- published: 15 Aug 2014

- views: 408888

- published: 11 Feb 2013

- views: 35305

- published: 31 Mar 2011

- views: 127078

- published: 12 Apr 2011

- views: 60924

- published: 20 Sep 2011

- views: 157280

An optical fiber (or optical fibre) is a flexible, transparent fiber made of a pure glass (silica) not much thicker than a human hair. It functions as a waveguide, or “light pipe”, to transmit light between the two ends of the fiber. The field of applied science and engineering concerned with the design and application of optical fibers is known as fiber optics. Optical fibers are widely used in fiber-optic communications, which permits transmission over longer distances and at higher bandwidths (data rates) than other forms of communication. Fibers are used instead of metal wires because signals travel along them with less loss and are also immune to electromagnetic interference. Fibers are also used for illumination, and are wrapped in bundles so that they may be used to carry images, thus allowing viewing in confined spaces. Specially-designed fibers are used for a variety of other applications, including sensors and fiber lasers.

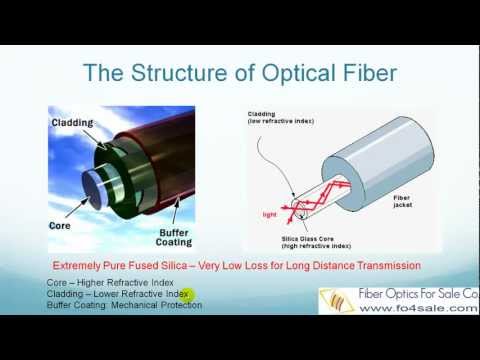

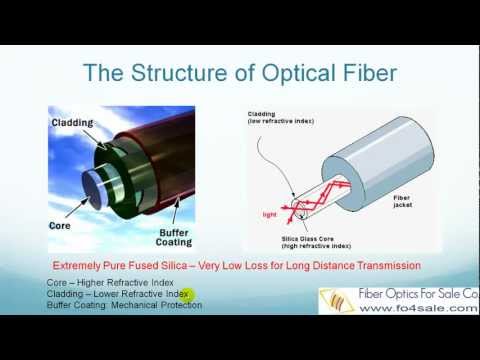

Optical fibers typically include a transparent core surrounded by a transparent cladding material with a lower index of refraction. Light is kept in the core by total internal reflection. This causes the fiber to act as a waveguide. Fibers that support many propagation paths or transverse modes are called multi-mode fibers (MMF), while those that only support a single mode are called single-mode fibers (SMF). Multi-mode fibers generally have a wider core diameter, and are used for short-distance communication links and for applications where high power must be transmitted. Single-mode fibers are used for most communication links longer than 1,050 meters (3,440 ft).

This article is licensed under the Creative Commons Attribution-ShareAlike 3.0 Unported License, which means that you can copy and modify it as long as the entire work (including additions) remains under this license.

- Loading...

-

5:36

5:36Fiber optic cables: How they work

Fiber optic cables: How they work -

4:15

4:15Fiber Optics, How it works??

Fiber Optics, How it works??Fiber Optics, How it works??

An optical fiber (or optical fibre) is a flexible, transparent fiber made of extruded glass (silica) or plastic, slightly thicker than a human hair. It can function as a waveguide, or “light pipe”, to transmit light between the two ends of the fiber. The field of applied science and engineering concerned with the design and application of optical fibers is known as fiber optics. Optical fibers are widely used in fiber-optic communications, where they permit transmission over longer distances and at higher bandwidths (data rates) than wire cables. Fibers are used instead of metal wires because signals travel along them with less loss and are also immune to electromagnetic interference. Fibers are also used for illumination, and are wrapped in bundles so that they may be used to carry images, thus allowing viewing in confined spaces. Specially designed fibers are used for a variety of other applications, including sensors and fiber lasers. Optical fibers typically include a transparent core surrounded by a transparent cladding material with a lower index of refraction. Light is kept in the core by total internal reflection. This causes the fiber to act as a waveguide. Fibers that support many propagation paths or transverse modes are called multi-mode fibers (MMF), while those that only support a single mode are called single-mode fibers (SMF). Multi-mode fibers generally have a wider core diameter, and are used for short-distance communication links and for applications where high power must be transmitted. Single-mode fibers are used for most communication links longer than 1,000 meters (3,300 ft). Joining lengths of optical fiber is more complex than joining electrical wire or cable. The ends of the fibers must be carefully cleaved, and then carefully spliced together with the cores perfectly aligned. A mechanical splice holds the ends of the fibers together mechanically, while fusion splicing uses heat to fuse the ends of the fibers together. Special optical fiber connectors for temporary or semi-permanent connections are also available. -

3:58

3:58How To Splice Fiber Optic cable Manually

How To Splice Fiber Optic cable ManuallyHow To Splice Fiber Optic cable Manually

You can manually splice the fiber patch cord with the help of the Procedure shown in the video. Now you can splice your patch cord. Consider the following step for manually splicing the patch cord: Step 1: Strip the Fiber Patch Cord as shown in the video. Step 2: Strip the other cable in the same way as in step 1. Step 3: Clean the fiber core with the solution. Step 4: Place the Splice Lock on the Fiber lock assembly as shown in the video. Step 5: Insert the Fiber patch cord in the Splice lock as shown. Step 6: Press the Fiber Assembly to manually splice the patch Cord. Your Patch Cord is ready. Product Link: http://mdrelectronics.com/ProductDisplay.asp?PID=3670 http://mdrelectronics.com/ProductDisplay.asp?PID=3672 What is Fiber Optics? Fiber optic cable in essence, is a hair-like glass conduit that carries virtually any type of signal from one point to another at light speed. In case you are wondering why light traveling through fiber optic cable does not actually travel at true light speed, it is because the glass that makes up fiber optic cable is denser than the vacuum of outer space where light can travel without disruption. Needless to say, a fiber optic light signal is still much faster and far superior to a copper based signal, which is why it has become so popular in the cable television, telecommunications and computer networking. Unlike copper based signals, fiber signals are not affected by external power sources or surges and there is no need for shielding or grounding. How are Fiber Optics used today? Today, practically every communication network contains fiber optics. In most cases, fiber optics are used because of their convenience. Fiber optic cable allows network builders to divide their network into smaller service areas that prevent large numbers of customers from being affected in an outage. The result is better service and customer relations. Fiber optic cable also gives them a fast return path, which they use for Internet and telephone connections, thereby increasing their revenue potential. The use of fiber optics is not just limited to communication networks. Cable and telephone providers often use fiber for its distance capabilities. Distance is also an advantage to industrial plants that use vast amounts of fiber primarily for its noise immunity. Utilities also prefer fiber for noise immunity, security and high bandwidth properties. The military uses fiber because it's nearly tap-proof and impossible to jam. Fiber is even used by the aviation and aerospace industries because of its smaller size and weight. What are the advantages of Fiber Optics over Copper wire? Fiber's extra distance capability and seemingly unlimited data rate makes it possible to do things not possible with copper wire. For example, you can install all the electronics for a network in one communications closet for a building and run straight to the desk with fiber. With copper, you can only transmit about 90 meters (less than 300 feet), thus requiring more telecom closets in each building. With fiber, you only need passive patch panels locally to allow for moves. Upgrades can be rather difficult with copper wire, but not with fiber because the real capacity of fiber is only partially utilized at today's network speed. Many use fiber to connect all their central offices and long distance switches because it has thousands of times the bandwidth of copper wire and can carry signals hundreds of times further before needing a repeater. The cable and telephone providers use fiber because it gives them greater reliability with the opportunity to offer new services, like digital phone service and Internet connections. They also use fiber for economic reasons, but their cost justification requires adopting new network architectures to take advantage of the fiber's strengths. Please subscribe to our YOUTUBE Channel: MX Electronics (MDRElex) You can also Like our Facebook Page: http://www.facebook.com/mxelectronics This video is a complete guide, however if you have any questions feel free to comment or send us an email on info@mdrelectronics.com or visit our website www.mdrelectronics.com If You Have Any Complaints, Queries Or Suggestion, Call Us On (022) 4253 6666 Or You Can Mail Us At info@mdrelectronics.com -

8:33

8:33Fiber Optic Termination- How to terminate fiber optic cable using Giganet Fibre Optic connectors

Fiber Optic Termination- How to terminate fiber optic cable using Giganet Fibre Optic connectorsFiber Optic Termination- How to terminate fiber optic cable using Giganet Fibre Optic connectors

http://www.giga-net.co.uk Terminating fibre optic SC, ST and LC connectors using the Giganet cold-cure fiber optic cold-cure and polishing method. -

4:47

4:47How It's Made, Fiber Optics.

How It's Made, Fiber Optics.How It's Made, Fiber Optics.

-

8:14

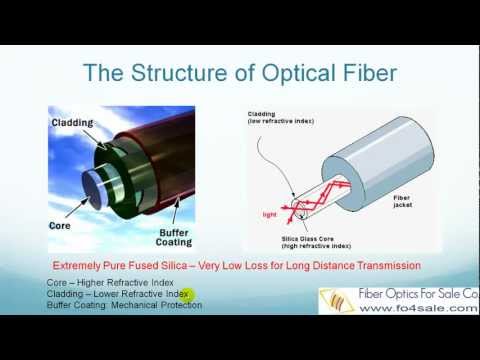

8:14What Are Fiber Optics? - FO4SALE.COM

What Are Fiber Optics? - FO4SALE.COMWhat Are Fiber Optics? - FO4SALE.COM

Download the PowerPoint file for this video here: http://www.slideshare.net/fiberoptics4sale/what-is-fiber-optic http://www.fiberoptics4sale.com - Fiber Optics Tutorial, Fiber Optics Cable, Fiber Optics Installation, Fiber Optics Splicing This picture shows a bunch of fiber enclosed in a single black color protective jacket. So how is light guided and travels inside the fiber? This video shows a beam of light that travels inside a water stream by total internal reflection. Optical fibers work the same way. So let's take a look. A glass fiber has a cylindrical structure and is composed of three layers. At the center is the core, core has higher refractive index. Outside of core is the cladding layer. Cladding layer has lower refractive index than the core. The third layer is a plastic buffer coating. This buffer coating doesn't affect the fiber's optical performance, it is there for mechanical protection only. The right picture shows how light is coupled into the fiber's core and bounced back and forth in the core and travels along the fiber. The core and cladding layers are all based on fused silica which is a type of glass. But this fused silica is extremely clear, with almost no impurities. This transparency is extremely important, so that the light can travel for a very long distance, such as hundreds of kilometers with minimum loss. This makes trans-Pacific and trans-continent fiber optic communications possible. Here comes the question. Why doesn't the light leak out of the fiber? That is why we have to explain the phenomenon of total internal reflection. The left picture shows Snell's the law which guides how light travels at the interface of the core and cladding. The core has a higher refractive index n = 1.5. The cladding has a lower refractive index n = 1.4. When light incidents at the interface between the core and cladding at different angles, some power is reflected back, and some power enters into the cladding which is refracted. But when we increase the incident angle to greater than a critical angle theta c, no more light enters into the cladding, all light is reflected back into the core. This phenomenon is called Total Internal Reflection. Here total means 100% of the power is reflected back into the core. The manufacturing of glass fibers go through two steps. In the first step a preform is made. This preform has exactly the same proportion of core and cladding as final fiber product, but in a much bigger size. It looks like a thick glass rod, as shown in the bottom picture. Then the preform is hanged at the top of a fiber drawing tower. The tower is a couple of stories tall as shown in the right picture. The preform is heated by a furnace which softens the glass. The softened glass drips and pulled downward by gravity. A diameter monitor carefully monitors the fiber's diameter, which usually is 125um. Then the coater deposits a layer of plastic buffer coating for mechanical protection, which usually is 250um in diameter. And finally, the fiber is winded onto a spool for storage and transportation. A basic fiber optic communication system must have at least three components. The light source, which usually is a laser. The laser is turned on and off quickly by a driving circuit. In this modulation process, the original electronic signal is translated into light signal. The second part is the fiber. The fiber's purpose is to transmit the light through a very long distance, such as from New York to Paris. And the third part is a photodetector. The photodetector detects the light and generates electronic current, in this process it translates the light signal back into electronic signal. This table list the most common high speed Ethernet standards. For 100 Mbps, copper supports up to 100 meters, while fiber supports up to 40 kilometers. For Gigbit Ethernet, copper supports still 100 meters, fiber supports 70 kilometers. For 10 Gigbit Ethernet, copper is 100 meters, and fiber is 80 kilometers. Now you see the difference. The bottom picture shows the size comparison between a copper cable and an optical fiber, both carries the same bandwidth. There is truly no match for fiber's bandwidth capabilities. In order to fully utilize the fiber's bandwidth, people are using WDM technologies to increases the bandwidth in tens of folds. WDM stands for Wavelength Division Multiplexer. What this means is that many different colors, or wavelengths, of light is put into a single fiber. This picture shows a simple 4 channel WDM, but there are 32 channels, 64 channels, or even more are available on the market now. Now imagine how many information can a single fiber carry. If each wavelength carries 40 Gbps signal, then a 10 channel WDM system can carry 400 Gbps. Not to mention a 100 channel WDM system. -

52:45

52:45On-Demand: Fiber Optic Network Design, Part 1

On-Demand: Fiber Optic Network Design, Part 1On-Demand: Fiber Optic Network Design, Part 1

Before fiber optic networks can be constructed, they must be properly designed, and once constructed they must be managed. Efficiency in these processes translate into lower cost layout and construction, more productive system migration and field operations, lower optical loss budget, and greater business profitability by bringing fiber to the desk. Join Terry Power as he discusses the steps involved in designing a successful fiber optic system. Webinar date: 4/8/15 -

1:22

1:22Shark Bites Fiber Optic Cables Undersea 15.8.2014

Shark Bites Fiber Optic Cables Undersea 15.8.2014Shark Bites Fiber Optic Cables Undersea 15.8.2014

Google is reinforcing its underwater fibre-optic cables to protect against future shark attacks Google is reinforcing its private underwater fibre-optic cables with an extra layer of protective material in order to protect its 100,000 miles of cables from sharks. Sharks and other fish are attracted to the cables, thought by some to be due to the electromagnetic signals emitted by the lines, but they are easily damaged. The cables already have existing protective materials designed to shelter them from the various dangers of the environment, but will now be coated with a 'Kevlar-like' material to provide even more protection. Fibre-optic cables are made of strands of glass, and are thus much less durable than copper cables. Google wants to prevent its own cables from sustaining further damage after seeing underwater surveillance footage of sharks biting the cables. IT Pro has contacted Google for more information on the plans and will update the story as soon as we know more. -

3:59

3:59What is Fiber Optics? | Mocomi Kids

What is Fiber Optics? | Mocomi KidsWhat is Fiber Optics? | Mocomi Kids

http://mocomi.com/ presents: What is Fiber Optics? Fiber optics or Optical Fibers are very thin and flexible strands of glass which are used today to transmit data over long distances with minimum loss. Watch this interesting video explaining what is fiber optics, how it works, uses and conclusion with the help of this animated learning module for kids. An optical fiber is a semi-flexible, transparent, and extremely thin strand of pure glass that has the diameter of a human hair. Thousands of these strands are arranged in bundles to make a thicker cable. Since glass is optically transparent we are able to send information-laden rays of light over long distances. A fiber optic cable is made up of five parts: Strands of glass that are bundled together to make one single channel of light called makes up the core. The diameter of the core dictates how much information can be sent and received at once. A protective sheath or coating around any structure or material is known as the cladding. In fiber optic cables the silica cladding increases the total internal reflection of the core. Therefore a light pulse can pass through the entire length of the fiber with little data loss. A layer of plastic surrounds the core and cladding to reinforce the fiber core. The coating provides extra protection and prevents the cable from bending too much. The strengthening fibers around the coating give added support to the coating especially when it comes to stretching tension. Finally all this is covered in the cable jacket like any other cable or wire. The only part of a fiber optic cable that carries data is the tiny core in the center but it has layer upon layer of protection because glass is extremely brittle and in order for it to function at its best, there can be no breaks in the fiber at all. Add to that the high cost of producing them and you will know why every precaution must be taken to prevent damage. To read more about fiber optics read: http://mocomi.com/fiber-optics/ For more cool physics videos and articles go to: http://mocomi.com/learn/science/physics/ Follow Mocomi Kids, on Facebook https://www.facebook.com/mocomikids/ on Twitter https://twitter.com/MocomiKids on Pinterest https://www.pinterest.com/mocomikids/ on Google+ https://plus.google.com/+mocomikids/ on LinkedIn https://www.linkedin.com/company/mocomi-kids -

4:45

4:45Understanding Fiber Optic Connector Types

Understanding Fiber Optic Connector TypesUnderstanding Fiber Optic Connector Types

This video reviews fiber optic connector types and where you might find them in your fiber optic network -

3:30

3:30Fiber Optic Splicing - Best Practices

Fiber Optic Splicing - Best PracticesFiber Optic Splicing - Best Practices

A close-up look at the proper procedure to perform a fusion splice. -

10:47

10:47CONDUX - Fiber Optic Cable Puller

CONDUX - Fiber Optic Cable PullerCONDUX - Fiber Optic Cable Puller

Learn more at: http://www.condux.com This video covers how to: 1. Install Pull Tape 2. Puller Set-Up 3. Position the Foot Control & Position the Capstan 4. Electronic Control System 5. Figure 8 Cable The Condux Fiber Optic Cable Puller sets the standard for safe, efficient pulling of fiber optic cable. Condux Fiber Optic Cable Pullers offer low self torque input for the most accurate tension measuring available. Unlike most hydraulic measuring systems, the Condux system is not affected by changes in temperature, component age, and power source. The puller also features a variable speed foot control and manual flow control valve for optimum pulling speed control.

- Achromatic lens

- AgInSbTe

- Aircraft

- Alfred Vail

- Alumina

- Aluminium

- Aluminium oxide

- Aluminosilicate

- Amplifier

- Annealing (glass)

- Applied science

- Aramid

- ARPANET

- Art

- Aspheric lens

- Attenuation

- Barium

- Basil Hirschowitz

- Bayonet

- Beacon

- Bell Labs

- Bessel function

- Bibcode

- Bioactive glass

- Bioglass

- BITNET

- Borescope

- Boron trioxide

- Borosilicate glass

- Cable jetting

- Cat-5

- Ceramic glaze

- Chalcogen

- Chalcogenide glass

- Charles K. Kao

- Charles Wheatstone

- Chemically inert

- Christmas tree

- Clarence Hansell

- Claude Chappe

- Cleave (fiber)

- Coaxial cable

- Cobalt glass

- Coherence (physics)

- Commercial signage

- Computer network

- Concentration

- Core (optical fiber)

- Corning Incorporated

- CorningWare

- Corrosion

- Coupling

- Cranberry glass

- Crown glass (optics)

- Crystal structure

- Crystallization

- Data cable

- David N. Payne

- Dealkalization

- Decibel

- Dense WDM

- Dentistry

- Dependent territory

- Dielectric

- Dielectric waveguide

- Diffraction

- Diffuse reflection

- Dispersion (optics)

- DNA microarray

- Donald Keck

- Dopant

- Double-clad fiber

- Drawing tower

- Drum (communication)

- Electric arc

- Electrical power

- Electrical telegraph

- Electromagnetism

- Electron

- Electropositive

- Elisha Gray

- Emmanuel Desurvire

- Endoscope

- Engineering

- Erbium

- Ethernet

- Evanescent wave

- Fax

- Fiber Bragg grating

- Fiber laser

- Fiber optic sensor

- Fiber optic sights

- Fiber pigtail

- Fiber tapping

- Fiber to the home

- Fiberscope

- Fibre Channel

- FidoNet

- Filling factor

- Flint glass

- Fluoride

- Fluoride glass

- Fluorine

- Fluorosilicate glass

- Frisbee

- FTTX

- Fused quartz

- Fusion splicing

- Gain medium

- Gap loss

- Garnet

- Gastroscope

- General Electric

- Geography

- Geometrical optics

- George A. Hockham

- Germanium dioxide

- GeSbTe

- Gigabit per second

- Glass

- Glass databases

- Glass electrode

- Glass ionomer cement

- Glass microsphere

- Glass production

- Glass transition

- Glass-ceramic

- Glass-coated wire

- Glass-to-metal seal

- Globalization

- Graded-index fiber

- Grain boundaries

- Guglielmo Marconi

- Guided ray

- Harold Hopkins

- Heinrich Lamm

- Heliograph

- High voltage

- History of radio

- Human hair

- Hydraulic telegraph

- Hydrogen darkening

- Hydroxyl

- Hydroxyl group

- Hygroscopy

- Imperial College

- Incoherent scatter

- Index of refraction

- Index-matching gel

- India

- Ingots

- Insulated glazing

- Intensity (physics)

- Intensity modulation

- Internet

- Invention

- Ion

- Ion implantation

- IR spectroscopy

- Jacques Babinet

- Jargon File

- Jean-Daniel Colladon

- Jet engine

- Johann Philipp Reis

- John Logie Baird

- John Tyndall

- Jun-ichi Nishizawa

- Kelvin

- Lanthanum

- Laser

- Laser diode

- Laser pumping

- Laser safety

- Lathe

- Lead glass

- Leaky mode

- Lee De Forest

- Lens (optics)

- Lens flare

- Light Peak

- Light pipe

- Light scattering

- Light tube

- Light-emitting diode

- Lightning

- Liquidus temperature

- LiTraCon

- Local area network

- London

- MACOR

- Manfred Börner

- Mass media

- Maxwell's equations

- Mechanical splice

- Megawatt

- Melting point

- Metal

- Metaphosphate

- Micrometre

- Microscopes

- Microwave

- Mid-infrared

- Milk glass

- Mobile telephony

- Modal bandwidth

- Modulation

- Modulator

- Multi-mode fiber

- Multiplexing

- Near infrared

- Near-infrared

- Nikola Tesla

- Nonimaging optics

- Numerical aperture

- Open fiber control

- Ophthalmology

- Optical aberration

- Optical amplifier

- Optical cable

- Optical fiber

- Optical fiber cable

- Optical imaging

- Optical interconnect

- Optical lens design

- Optical mesh network

- Optical path length

- Optical power meter

- Optical pumping

- Optical waveguide

- Optical wireless

- Optics

- Optoelectronics

- Oxygen

- Oxyhydrogen

- Packet switching

- Parabola

- Paris

- Periodic table

- Perpendicular

- Peter C. Schultz

- Phase (waves)

- Philo Farnsworth

- Phosphate glass

- Phosphorus pentoxide

- Photochromic lens

- Photonic crystal

- Photophone

- Photosensitive glass

- Photovoltaic cell

- Physics experiment

- Polarization (waves)

- Porous glass

- Portal Electronics

- Power generation

- Pressure

- Prince Rupert's Drop

- PubMed Identifier

- Pyrometer

- Quartz

- Radiation

- Radio network

- Radio waves

- Radioactive waste

- Radiotelephone

- Rare earth element

- Ray (optics)

- Refraction

- Refractive index

- Refractive indices

- Reginald Fessenden

- Resin

- Robert D. Maurer

- Sagnac effect

- Sapphire

- Scattering

- Schott AG

- Scintillator

- Selenium

- Self-cleaning glass

- Semaphore line

- Sensor

- Silica

- Silica glass

- Silicate glass

- Silver

- Sine

- Single-mode fiber

- Soda-lime glass

- Sodium

- Sol-gel

- Soliton

- Soluble glass

- Sovereign state

- Sovereign territory

- Speckle

- Spectroscopy

- Speed of light

- Step-index profile

- Stimulated emission

- Strain relief

- Sulfur

- Supercooling

- Surface

- Surface normal

- Swarovski

- Telecommunication

- Telefunken

- Telegraphy

- Telephone line

- Television network

- Telex

- Tellurite glass

- Tellurium

- Temperature

- Template Asia topic

- Tetrahedra

- The Telephone Cases

- Thermometry

- Thermophoresis

- Tim Berners-Lee

- Titanium

- Tohoku University

- TOSLINK

- Toughened glass

- Translation stage

- Transmission medium

- Transparent ceramics

- Transverse mode

- Ultraviolet

- Uranium glass

- Vacuum

- Vector soliton

- Videotelephony

- Vint Cerf

- Viscosity

- Visible spectrum

- Vitreous enamel

- Vitrification

- Vladimir K. Zworykin

- Waveguide (optics)

- Wavelength

- Wavelength shifter

- Wide area network

- Windshield

- Wireless network

- Wiretapping

- Wood's glass

- World Wide Web

- XENPAK

- Yttria

- ZBLAN

- Zerodur

- Zirconium

Fiber Optic

ALBUMS

- Boccaccio Beach released: 2001

- Serious Beats 36 released: 2001

Boccaccio Beach

Released 2001- add to main playlist Play in Full Screen Let You Free

- add to main playlist Play in Full Screen Meet Her at the Love Parade 2001

- add to main playlist Play in Full Screen Sushi

- add to main playlist Play in Full Screen Black Magic

- add to main playlist Play in Full Screen De-generation

- add to main playlist Play in Full Screen Acid Kills Your Brain

- add to main playlist Play in Full Screen Narcotic

- add to main playlist Play in Full Screen Hard One

- add to main playlist Play in Full Screen The Last Resort

- add to main playlist Play in Full Screen Kisses of Fire

- add to main playlist Play in Full Screen What About U

- add to main playlist Play in Full Screen Music Will Bring Us Together

- add to main playlist Play in Full Screen White Powder

- add to main playlist Play in Full Screen This Is the Ultimate

- add to main playlist Play in Full Screen I Love You

- add to main playlist Play in Full Screen Cocaine in My Brain

- add to main playlist Play in Full Screen Horizon

- add to main playlist Play in Full Screen My Impression

- add to main playlist Play in Full Screen Upside Down

- add to main playlist Play in Full Screen Easy Tone

Serious Beats 36

Released 2001- add to main playlist Play in Full Screen Such Is Live (Extended Version)

- add to main playlist Play in Full Screen Derb (Arome Mix)

- add to main playlist Play in Full Screen The Wall (Warehouse Mix)

- add to main playlist Play in Full Screen Too Many Times (Energy Mix)

- add to main playlist Play in Full Screen On the Move (DuMonde Mix)

- add to main playlist Play in Full Screen Monotonous

- add to main playlist Play in Full Screen Lift Me Up (Barthezz Uplifting Remix)

- add to main playlist Play in Full Screen The Beginning (Original Take)

- add to main playlist Play in Full Screen Upside Down (Never Put Your Feet Back Mix)

- add to main playlist Play in Full Screen Technorocker (Insider vs. Ghost Remix)

- add to main playlist Play in Full Screen 10 in 01 (original)

- add to main playlist Play in Full Screen Technology

- add to main playlist Play in Full Screen Indian Requiem (Original Mix)

- add to main playlist Play in Full Screen Da Noise

- add to main playlist Play in Full Screen The Real Life

-

-

Fiber Optics, How it works??

An optical fiber (or optical fibre) is a flexible, transparent fiber made of extruded glass (silica) or plastic, slightly thicker than a human hair. It can function as a waveguide, or “light pipe”, to transmit light between the two ends of the fiber. The field of applied science and engineering concerned with the design and application of optical fibers is known as fiber optics. Optical fibers are widely used in fiber-optic communications, where they permit transmission over longer distances and at higher bandwidths (data rates) than wire cables. Fibers are used instead of metal wires because signals travel along them with less loss and are also immune to electromagnetic interference. Fibers are also used for illumination, and are wrapped in bundles so that they may be used to carry imag... -

How To Splice Fiber Optic cable Manually

You can manually splice the fiber patch cord with the help of the Procedure shown in the video. Now you can splice your patch cord. Consider the following step for manually splicing the patch cord: Step 1: Strip the Fiber Patch Cord as shown in the video. Step 2: Strip the other cable in the same way as in step 1. Step 3: Clean the fiber core with the solution. Step 4: Place the Splice Lock on the Fiber lock assembly as shown in the video. Step 5: Insert the Fiber patch cord in the Splice lock as shown. Step 6: Press the Fiber Assembly to manually splice the patch Cord. Your Patch Cord is ready. Product Link: http://mdrelectronics.com/ProductDisplay.asp?PID=3670 http://mdrelectronics.com/ProductDisplay.asp?PID=3672 What is Fiber Optics? Fiber optic cable in essence, is a hair-like gla... -

Fiber Optic Termination- How to terminate fiber optic cable using Giganet Fibre Optic connectors

http://www.giga-net.co.uk Terminating fibre optic SC, ST and LC connectors using the Giganet cold-cure fiber optic cold-cure and polishing method. -

How It's Made, Fiber Optics.

-

What Are Fiber Optics? - FO4SALE.COM

Download the PowerPoint file for this video here: http://www.slideshare.net/fiberoptics4sale/what-is-fiber-optic http://www.fiberoptics4sale.com - Fiber Optics Tutorial, Fiber Optics Cable, Fiber Optics Installation, Fiber Optics Splicing This picture shows a bunch of fiber enclosed in a single black color protective jacket. So how is light guided and travels inside the fiber? This video shows a beam of light that travels inside a water stream by total internal reflection. Optical fibers work the same way. So let's take a look. A glass fiber has a cylindrical structure and is composed of three layers. At the center is the core, core has higher refractive index. Outside of core is the cladding layer. Cladding layer has lower refractive index than the core. The third layer is a plastic... -

On-Demand: Fiber Optic Network Design, Part 1

Before fiber optic networks can be constructed, they must be properly designed, and once constructed they must be managed. Efficiency in these processes translate into lower cost layout and construction, more productive system migration and field operations, lower optical loss budget, and greater business profitability by bringing fiber to the desk. Join Terry Power as he discusses the steps involved in designing a successful fiber optic system. Webinar date: 4/8/15 -

Shark Bites Fiber Optic Cables Undersea 15.8.2014

Google is reinforcing its underwater fibre-optic cables to protect against future shark attacks Google is reinforcing its private underwater fibre-optic cables with an extra layer of protective material in order to protect its 100,000 miles of cables from sharks. Sharks and other fish are attracted to the cables, thought by some to be due to the electromagnetic signals emitted by the lines, but they are easily damaged. The cables already have existing protective materials designed to shelter them from the various dangers of the environment, but will now be coated with a 'Kevlar-like' material to provide even more protection. Fibre-optic cables are made of strands of glass, and are thus much less durable than copper cables. Google wants to prevent its own cables from sustaining further d... -

What is Fiber Optics? | Mocomi Kids

http://mocomi.com/ presents: What is Fiber Optics? Fiber optics or Optical Fibers are very thin and flexible strands of glass which are used today to transmit data over long distances with minimum loss. Watch this interesting video explaining what is fiber optics, how it works, uses and conclusion with the help of this animated learning module for kids. An optical fiber is a semi-flexible, transparent, and extremely thin strand of pure glass that has the diameter of a human hair. Thousands of these strands are arranged in bundles to make a thicker cable. Since glass is optically transparent we are able to send information-laden rays of light over long distances. A fiber optic cable is made up of five parts: Strands of glass that are bundled together to make one single channel of light... -

Understanding Fiber Optic Connector Types

This video reviews fiber optic connector types and where you might find them in your fiber optic network -

Fiber Optic Splicing - Best Practices

A close-up look at the proper procedure to perform a fusion splice. -

CONDUX - Fiber Optic Cable Puller

Learn more at: http://www.condux.com This video covers how to: 1. Install Pull Tape 2. Puller Set-Up 3. Position the Foot Control & Position the Capstan 4. Electronic Control System 5. Figure 8 Cable The Condux Fiber Optic Cable Puller sets the standard for safe, efficient pulling of fiber optic cable. Condux Fiber Optic Cable Pullers offer low self torque input for the most accurate tension measuring available. Unlike most hydraulic measuring systems, the Condux system is not affected by changes in temperature, component age, and power source. The puller also features a variable speed foot control and manual flow control valve for optimum pulling speed control.

Fiber optic cables: How they work

- Order: Reorder

- Duration: 5:36

- Updated: 20 Jun 2011

- views: 1325847

Fiber Optics, How it works??

- Order: Reorder

- Duration: 4:15

- Updated: 22 Feb 2015

- views: 18898

- published: 22 Feb 2015

- views: 18898

How To Splice Fiber Optic cable Manually

- Order: Reorder

- Duration: 3:58

- Updated: 15 Jul 2011

- views: 257794

- published: 15 Jul 2011

- views: 257794

Fiber Optic Termination- How to terminate fiber optic cable using Giganet Fibre Optic connectors

- Order: Reorder

- Duration: 8:33

- Updated: 07 May 2009

- views: 405775

- published: 07 May 2009

- views: 405775

How It's Made, Fiber Optics.

- Order: Reorder

- Duration: 4:47

- Updated: 16 Nov 2011

- views: 492045

- published: 16 Nov 2011

- views: 492045

What Are Fiber Optics? - FO4SALE.COM

- Order: Reorder

- Duration: 8:14

- Updated: 16 Feb 2012

- views: 123689

- published: 16 Feb 2012

- views: 123689

On-Demand: Fiber Optic Network Design, Part 1

- Order: Reorder

- Duration: 52:45

- Updated: 15 Apr 2015

- views: 11257

- published: 15 Apr 2015

- views: 11257

Shark Bites Fiber Optic Cables Undersea 15.8.2014

- Order: Reorder

- Duration: 1:22

- Updated: 15 Aug 2014

- views: 408888

- published: 15 Aug 2014

- views: 408888

What is Fiber Optics? | Mocomi Kids

- Order: Reorder

- Duration: 3:59

- Updated: 11 Feb 2013

- views: 35305

- published: 11 Feb 2013

- views: 35305

Understanding Fiber Optic Connector Types

- Order: Reorder

- Duration: 4:45

- Updated: 31 Mar 2011

- views: 127078

- published: 31 Mar 2011

- views: 127078

Fiber Optic Splicing - Best Practices

- Order: Reorder

- Duration: 3:30

- Updated: 12 Apr 2011

- views: 60924

- published: 12 Apr 2011

- views: 60924

CONDUX - Fiber Optic Cable Puller

- Order: Reorder

- Duration: 10:47

- Updated: 20 Sep 2011

- views: 157280

- published: 20 Sep 2011

- views: 157280

- Playlist

- Chat

- Playlist

- Chat

Fiber optic cables: How they work

- Report rights infringement

- published: 20 Jun 2011

- views: 1325847

Fiber Optics, How it works??

- Report rights infringement

- published: 22 Feb 2015

- views: 18898

How To Splice Fiber Optic cable Manually

- Report rights infringement

- published: 15 Jul 2011

- views: 257794

Fiber Optic Termination- How to terminate fiber optic cable using Giganet Fibre Optic connectors

- Report rights infringement

- published: 07 May 2009

- views: 405775

How It's Made, Fiber Optics.

- Report rights infringement

- published: 16 Nov 2011

- views: 492045

What Are Fiber Optics? - FO4SALE.COM

- Report rights infringement

- published: 16 Feb 2012

- views: 123689

On-Demand: Fiber Optic Network Design, Part 1

- Report rights infringement

- published: 15 Apr 2015

- views: 11257

Shark Bites Fiber Optic Cables Undersea 15.8.2014

- Report rights infringement

- published: 15 Aug 2014

- views: 408888

What is Fiber Optics? | Mocomi Kids

- Report rights infringement

- published: 11 Feb 2013

- views: 35305

Understanding Fiber Optic Connector Types

- Report rights infringement

- published: 31 Mar 2011

- views: 127078

Fiber Optic Splicing - Best Practices

- Report rights infringement

- published: 12 Apr 2011

- views: 60924

CONDUX - Fiber Optic Cable Puller

- Report rights infringement

- published: 20 Sep 2011

- views: 157280

Brazil Scientists Seek to Unravel Mystery of Zika Twins

Edit Voa News 07 May 2016RNC Chairman Says Trump "Trying" To Rein In Craziness Surrounding His Campaign

Edit WorldNews.com 06 May 2016Officials fear massive Canada wildfire could double in size

Edit Fox News 07 May 2016Lauryn Hill finally returns for Munhall concert Wednesday

Edit Pittsburgh Post-Gazette 07 May 2016Oil tanker washes up on Liberia beach with no crew or lifeboats

Edit The Guardian 06 May 2016Tucows Bans Pop-Up Ads, Goes Ad-Free

Edit Slashdot 08 May 2016"Composite Materials: Low Velocity Impact Phenomenon" (Universidad Politécnica de Madrid)

Edit Public Technologies 08 May 2016Email these recipes to your kids now for a great Mother’s Day brunch

Edit Naples Daily News 08 May 2016I made the choice to be stronger than my cancer

Edit Toronto Sun 08 May 2016EAMCET hall-tickets from tomorrow

Edit The Hindu 08 May 2016New Carlisle unable to download body cam footage

Edit Springfield News-Sun 07 May 2016Tired of waiting, rich enclave may build fast Internet

Edit San Diego Union-Tribune 07 May 2016Unveiled Webb Telescope Mirrors Mesmerize in ‘Golden’ Glory

Edit Universe Today 07 May 2016Bartlett optics firm gets jump on 2017 solar eclipse

Edit Commercial Appeal 07 May 2016Bartlett firm sets goal to sell 100 million glasses for 2017 total eclipse

Edit Commercial Appeal 07 May 2016Nutrition: Before heading out, plan to take along a healthy meal

Edit LA Daily News 07 May 2016Bastrop and Smithville city, school elections to be decided Saturday

Edit Austin American Statesman 07 May 2016- 1

- 2

- 3

- 4

- 5

- Next page »