- published: 11 Oct 2010

- views: 171921

-

remove the playlistPrestressed Concrete

-

remove the playlistLongest Videos

- remove the playlistPrestressed Concrete

- remove the playlistLongest Videos

- published: 23 Jan 2013

- views: 179791

- published: 29 Jun 2016

- views: 7943

- published: 18 Jun 2013

- views: 22149

- published: 21 Oct 2015

- views: 4404

- published: 10 Sep 2011

- views: 144272

- published: 24 Jun 2013

- views: 17505

- published: 30 Jul 2014

- views: 10276

Prestressed concrete

Prestressed concrete is the method for overcoming concrete's natural weakness in tension. It can be used to produce beams, floors or bridges with a longer span than is practical with ordinary reinforced concrete. It is often used in commercial and residential construction as a foundation slab. Prestressing tendons (generally of high tensile strength steel cable or rods) are used to provide a clamping load which produces a compressive stress that balances the tensile stress that the concrete compression member would otherwise experience due to a bending load. Traditional reinforced concrete is based on the use of steel reinforcement bars, rebars, inside poured concrete. Prestressing can be accomplished in three ways: pre-tensioned concrete, and bonded or unbonded post-tensioned concrete.

Pre-tensioned concrete

Pre-tensioned concrete is cast around steel tendons—cables or bars—while they are under tension. The concrete bonds to the tendons as it cures, and when the tension is released it is transferred to the concrete as compression by static friction. Tension subsequently imposed on the concrete is transferred directly to the tendons.

This article is licensed under the Creative Commons Attribution-ShareAlike 3.0 Unported License, which means that you can copy and modify it as long as the entire work (including additions) remains under this license.

- Loading...

-

2:04

2:04Prestressed Concrete - Milbury Systems

Prestressed Concrete - Milbury SystemsPrestressed Concrete - Milbury Systems

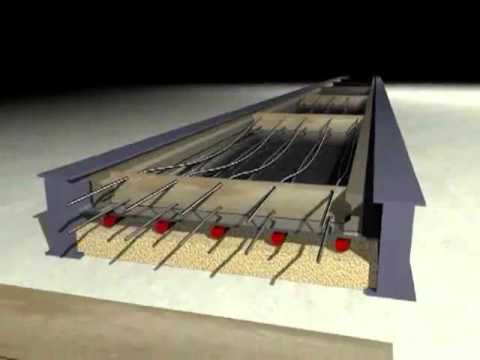

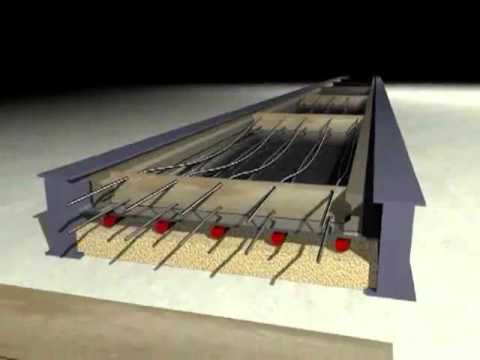

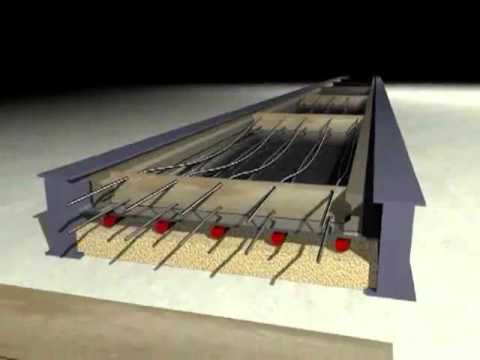

An illustration of prestressed concrete production by Milbury Systems an Eleco Company. Prestressed concrete is a method of overcoming concrete's natural weaknesses. It can be used to produced longer spans than is practical with standard reinforced concrete. Milbury Systems manufactures a number of precast and prestressed products. -

6:52

6:52Q1. How does a prestressed precast concrete bridge beam work?

Q1. How does a prestressed precast concrete bridge beam work?Q1. How does a prestressed precast concrete bridge beam work?

How does a pre-stressed concrete bridge beam work? The strands inside the beam would be compressed applying a significant amount of force by pulling them back, the concrete is casted around the strand, then releasing the strands applying compressing force into the beam. Watch a video tutorial by Steve Lowe, Chief Design Engineer at Shay Murtagh Precast. Bridge Beams, Culverts, Retaining Walls, Parapets and Copings are only some of the products we manufacture for the Road/Highway Sector. With a proven track record in design, production along with our in house logistics and transport crews we have become a leading supplier to major infrastructure projects in the UK and Ireland. A short film describing Shay Murtagh's history, its present and its vision, Shay Murtagh Precast started as an Irish Family company, becoming one of the leading manufacturers of precast concrete products in the UK and Ireland, being the first concrete company to have completed the full suite of management system. With over 40 years experience, Shay Murtagh Precast are industry leaders in the field of Precast Concrete Solutions. Highest Standards Undertaking every aspect of the process – design, manufacture and delivery of the product, we provide assurance to our clients that only the highest standards have been applied. Regardless of the scale of the project our capability to design and produce precast components to our clients requirements has been proven in partnering to the largest infrastructure projects in the UK and Ireland. Industry Leaders Our technical expertise to develop bespoke precast elements has shown our Company setting industry benchmarks and pushing development of off-site solutions. It is this attention to detail that has resulted in Shay Murtagh Precast leading the way in Precast Concrete Solutions throughout the UK and Ireland. Please contact us at sales@shaymurtagh.co.uk -

7:17

7:17Civil Engineering-Post tesion Concrete -construction.

Civil Engineering-Post tesion Concrete -construction.Civil Engineering-Post tesion Concrete -construction.

Prestressed concrete is a method for overcoming concrete's natural weakness in tension. It can be used to produce beams, floors or bridges with a longer span than is practical with ordinary reinforced concrete. Prestressing tendons (generally of high tensile steel cable or rods) are used to provide a clamping load which produces a compressive stress that balances the tensile stress that the concrete compression member would otherwise experience due to a bending load. Traditional reinforced concrete is based on the use of steel reinforcement bars, rebars, inside poured concrete. Please share and subscribe my Chanel.Thank you. Link: https://youtu.be/71AfIbZK1PU -

28:42

28:42Prestressed Concrete (Introduction) PC1

Prestressed Concrete (Introduction) PC1Prestressed Concrete (Introduction) PC1

This lecture is a part of CS3001 Concrete Engineering subject for the third year Civil Engineering students at James Cook University, Townsville Australia. Though the design examples mentioned in this lecture are based on Australian Standards AS3600-2009, the fundamental design concepts will be applicable anywhere. -

5:04

5:04What is prestressed concrete? - Bare Essentials of Prestressed Concrete with Prof Chris Burgoyne Pt1

What is prestressed concrete? - Bare Essentials of Prestressed Concrete with Prof Chris Burgoyne Pt1What is prestressed concrete? - Bare Essentials of Prestressed Concrete with Prof Chris Burgoyne Pt1

World-leading concrete expert Professor Chris Burgoyne introduces viewers to pre-stressed concrete. This is the third in the Bare Essentials of Concrete series: the key things people who are studying construction or who are working in construction need to understand about concrete. Professor Burgoyne is head of the Structures Lab at the University of Cambridge. In this video he describes the principles behind pre-stressed concrete, its properties and applications and how engineers use the principle in structures. Learning outcomes The effect of applying compressive force to connected elements. How a compressive force eliminates tension in a beam. The advantages compared with reinforced concrete. About the Bare Essentials of Concrete Series This video is part of the Bare Essentials of Concrete Series, funded by CITB and Construct, in which Professorr Chris Burgoyne draws on his many years of practice as a leading researcher in concrete and in teaching to provide viewers with what he regards to be the key knowledge that construction professionals need to understand about concrete. Accompanying this series are two related series: the Bare Essentials of Concrete; and the Bare Essentials of Reinforced Concrete. This work is licensed under the Creative Commons Attribution-NonCommercial 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/b... -

1:14

1:14Prestress Concrete Beam - Animation

Prestress Concrete Beam - AnimationPrestress Concrete Beam - Animation

3D Animation for prestressing concrete beam -

11:20

11:20Video for prestressed concrete (with subtitle)

Video for prestressed concrete (with subtitle)Video for prestressed concrete (with subtitle)

-

2:05

2:05Civil Engineering: Prestressed Concrete

Civil Engineering: Prestressed ConcreteCivil Engineering: Prestressed Concrete

Prestressed concrete is a method for overcoming concrete's natural weakness in tension. It can be used to produce beams, floors or bridges with a longer span than is practical with ordinary reinforced concrete. Prestressing tendons (generally of high tensile steel cable or rods) are used to provide a clamping load which produces a compressive stress that balances the tensile stress that the concrete compression member would otherwise experience due to a bending load. Traditional reinforced concrete is based on the use of steel reinforcement bars, rebars, inside poured concrete. Video by Elecosoft plc: http://www.eleco.com/ -

22:59

22:59Prestressed Concrete (Equivalent Load Concepts) PC4

Prestressed Concrete (Equivalent Load Concepts) PC4Prestressed Concrete (Equivalent Load Concepts) PC4

This lecture is a part of CS3001 Concrete Engineering subject for the third year Civil Engineering students at James Cook University, Townsville Australia. Though the design examples mentioned in this lecture are based on Australian Standards AS3600-2009, the fundamental design concepts will be applicable anywhere. -

6:42

6:42Paul - Prestressed Concrete Technology in use

Paul - Prestressed Concrete Technology in usePaul - Prestressed Concrete Technology in use

Paul supply all installation components, machines and accessories for prestressing on casting beds. They include the permanent components, such as abutment anchor posts, transverse anchor plates etc. Also when choosing mobile stressing equipment, our large product range always provides the appropriate solution: - Single-wire stressing jacks from 30 to 300 kN prestressing force - Screw jacks - Twin ram jacks - Pump units for stressing jacks, steel cutters, ... - Detensioning pump units - Detensioning cylinders from 200 to 10000 kN - Wire/strand pushing machines - Special detensioning anchors

-

Prestressed Concrete - Milbury Systems

An illustration of prestressed concrete production by Milbury Systems an Eleco Company. Prestressed concrete is a method of overcoming concrete's natural weaknesses. It can be used to produced longer spans than is practical with standard reinforced concrete. Milbury Systems manufactures a number of precast and prestressed products.

published: 11 Oct 2010 -

Q1. How does a prestressed precast concrete bridge beam work?

How does a pre-stressed concrete bridge beam work? The strands inside the beam would be compressed applying a significant amount of force by pulling them back, the concrete is casted around the strand, then releasing the strands applying compressing force into the beam. Watch a video tutorial by Steve Lowe, Chief Design Engineer at Shay Murtagh Precast. Bridge Beams, Culverts, Retaining Walls, Parapets and Copings are only some of the products we manufacture for the Road/Highway Sector. With a proven track record in design, production along with our in house logistics and transport crews we have become a leading supplier to major infrastructure projects in the UK and Ireland. A short film describing Shay Murtagh's history, its present and its vision, Shay Murtagh Precast started as an Ir...

published: 23 Jan 2013 -

Civil Engineering-Post tesion Concrete -construction.

Prestressed concrete is a method for overcoming concrete's natural weakness in tension. It can be used to produce beams, floors or bridges with a longer span than is practical with ordinary reinforced concrete. Prestressing tendons (generally of high tensile steel cable or rods) are used to provide a clamping load which produces a compressive stress that balances the tensile stress that the concrete compression member would otherwise experience due to a bending load. Traditional reinforced concrete is based on the use of steel reinforcement bars, rebars, inside poured concrete. Please share and subscribe my Chanel.Thank you. Link: https://youtu.be/71AfIbZK1PU

published: 29 Jun 2016 -

Prestressed Concrete (Introduction) PC1

This lecture is a part of CS3001 Concrete Engineering subject for the third year Civil Engineering students at James Cook University, Townsville Australia. Though the design examples mentioned in this lecture are based on Australian Standards AS3600-2009, the fundamental design concepts will be applicable anywhere.

published: 18 Jun 2013 -

What is prestressed concrete? - Bare Essentials of Prestressed Concrete with Prof Chris Burgoyne Pt1

World-leading concrete expert Professor Chris Burgoyne introduces viewers to pre-stressed concrete. This is the third in the Bare Essentials of Concrete series: the key things people who are studying construction or who are working in construction need to understand about concrete. Professor Burgoyne is head of the Structures Lab at the University of Cambridge. In this video he describes the principles behind pre-stressed concrete, its properties and applications and how engineers use the principle in structures. Learning outcomes The effect of applying compressive force to connected elements. How a compressive force eliminates tension in a beam. The advantages compared with reinforced concrete. About the Bare Essentials of Concrete Series This video is part of the Bare Essentials of ...

published: 21 Oct 2015 -

Prestress Concrete Beam - Animation

3D Animation for prestressing concrete beam

published: 04 Apr 2016 -

Video for prestressed concrete (with subtitle)

published: 04 Oct 2013 -

Civil Engineering: Prestressed Concrete

Prestressed concrete is a method for overcoming concrete's natural weakness in tension. It can be used to produce beams, floors or bridges with a longer span than is practical with ordinary reinforced concrete. Prestressing tendons (generally of high tensile steel cable or rods) are used to provide a clamping load which produces a compressive stress that balances the tensile stress that the concrete compression member would otherwise experience due to a bending load. Traditional reinforced concrete is based on the use of steel reinforcement bars, rebars, inside poured concrete. Video by Elecosoft plc: http://www.eleco.com/

published: 10 Sep 2011 -

Prestressed Concrete (Equivalent Load Concepts) PC4

This lecture is a part of CS3001 Concrete Engineering subject for the third year Civil Engineering students at James Cook University, Townsville Australia. Though the design examples mentioned in this lecture are based on Australian Standards AS3600-2009, the fundamental design concepts will be applicable anywhere.

published: 24 Jun 2013 -

Paul - Prestressed Concrete Technology in use

Paul supply all installation components, machines and accessories for prestressing on casting beds. They include the permanent components, such as abutment anchor posts, transverse anchor plates etc. Also when choosing mobile stressing equipment, our large product range always provides the appropriate solution: - Single-wire stressing jacks from 30 to 300 kN prestressing force - Screw jacks - Twin ram jacks - Pump units for stressing jacks, steel cutters, ... - Detensioning pump units - Detensioning cylinders from 200 to 10000 kN - Wire/strand pushing machines - Special detensioning anchors

published: 30 Jul 2014

Prestressed Concrete - Milbury Systems

- Order: Reorder

- Duration: 2:04

- Updated: 11 Oct 2010

- views: 171921

- published: 11 Oct 2010

- views: 171921

Q1. How does a prestressed precast concrete bridge beam work?

- Order: Reorder

- Duration: 6:52

- Updated: 23 Jan 2013

- views: 179791

- published: 23 Jan 2013

- views: 179791

Civil Engineering-Post tesion Concrete -construction.

- Order: Reorder

- Duration: 7:17

- Updated: 29 Jun 2016

- views: 7943

- published: 29 Jun 2016

- views: 7943

Prestressed Concrete (Introduction) PC1

- Order: Reorder

- Duration: 28:42

- Updated: 18 Jun 2013

- views: 22149

- published: 18 Jun 2013

- views: 22149

What is prestressed concrete? - Bare Essentials of Prestressed Concrete with Prof Chris Burgoyne Pt1

- Order: Reorder

- Duration: 5:04

- Updated: 21 Oct 2015

- views: 4404

- published: 21 Oct 2015

- views: 4404

Prestress Concrete Beam - Animation

- Order: Reorder

- Duration: 1:14

- Updated: 04 Apr 2016

- views: 1720

Video for prestressed concrete (with subtitle)

- Order: Reorder

- Duration: 11:20

- Updated: 04 Oct 2013

- views: 31548

- published: 04 Oct 2013

- views: 31548

Civil Engineering: Prestressed Concrete

- Order: Reorder

- Duration: 2:05

- Updated: 10 Sep 2011

- views: 144272

- published: 10 Sep 2011

- views: 144272

Prestressed Concrete (Equivalent Load Concepts) PC4

- Order: Reorder

- Duration: 22:59

- Updated: 24 Jun 2013

- views: 17505

- published: 24 Jun 2013

- views: 17505

Paul - Prestressed Concrete Technology in use

- Order: Reorder

- Duration: 6:42

- Updated: 30 Jul 2014

- views: 10276

- published: 30 Jul 2014

- views: 10276

-

Design of Prestressed Concrete Lecture #1 2015 - Dirk Bondy

Introduction to Prestressed Concrete

published: 06 Oct 2015 -

Design of Prestressed Concrete Lecture #2 2015 - Dirk Bondy

Introduction to Equivalent Loads

published: 06 Oct 2015 -

Precast Prestressed Concrete (9/15/2010) - Full

Marty McIntyre of PCI speaks to Eastern Illinois students about the PreCast Concrete Industry and the work process involved.

published: 10 Apr 2012 -

Architectural & Structural Precast Prestressed Concrete (Full Video)

Dr. Wafeek Wahby, a Professor in the School of Technology at Eastern Illinois University, takes his class on a field trip to County Materials Corporation in Champaign, Illinois and Lombard Architectural Precast Products in Alsip, Illinois. The field trip was co-sponsored by Marty McIntyre, Executive Director of PCI of Illinois.

published: 10 Apr 2012 -

Prestressed Concrete (Prestress loss) PC6

This lecture is a part of CS3001 Concrete Engineering subject for the third year Civil Engineering students at James Cook University, Townsville Australia. Though the design examples mentioned in this lecture are based on Australian Standards AS3600-2009, the fundamental design concepts will be applicable anywhere.

published: 24 Jun 2013 -

-

MiBridge Seminar - Infill Prestressed Concrete Bridge Design - midas Civil

Analyzing infill prestressed concrete bridges requires consideration of many factors such as staged sequencing analysis, time-dependent materials and tendon loss to just name a few. Furthermore, it is hard to find a FEM program that contains an intuitive modeling tool relative to various construction methods. Through this session, steps on how midas Civil is able to assist the engineer in efficiently modeling an infill prestressed concrete bridges with staged construction information. In addition to this the automated moving load feature will be used to carry the moving load analysis.

published: 14 May 2016 -

Precast Prestressed Concrete (Fall 2006) - Full Video

Marty McIntyre of PCI speaks to Eastern Illinois students about the PreCast Concrete Industry and the work process involved.

published: 09 Apr 2012

Design of Prestressed Concrete Lecture #1 2015 - Dirk Bondy

- Order: Reorder

- Duration: 122:10

- Updated: 06 Oct 2015

- views: 2360

Design of Prestressed Concrete Lecture #2 2015 - Dirk Bondy

- Order: Reorder

- Duration: 105:09

- Updated: 06 Oct 2015

- views: 1980

Precast Prestressed Concrete (9/15/2010) - Full

- Order: Reorder

- Duration: 65:34

- Updated: 10 Apr 2012

- views: 6554

- published: 10 Apr 2012

- views: 6554

Architectural & Structural Precast Prestressed Concrete (Full Video)

- Order: Reorder

- Duration: 56:24

- Updated: 10 Apr 2012

- views: 841

- published: 10 Apr 2012

- views: 841

Prestressed Concrete (Prestress loss) PC6

- Order: Reorder

- Duration: 20:07

- Updated: 24 Jun 2013

- views: 5470

- published: 24 Jun 2013

- views: 5470

Lecture-8-Losses in Prestress

- Order: Reorder

- Duration: 59:29

- Updated: 11 Dec 2007

- views: 15323

MiBridge Seminar - Infill Prestressed Concrete Bridge Design - midas Civil

- Order: Reorder

- Duration: 36:49

- Updated: 14 May 2016

- views: 251

- published: 14 May 2016

- views: 251

Precast Prestressed Concrete (Fall 2006) - Full Video

- Order: Reorder

- Duration: 76:29

- Updated: 09 Apr 2012

- views: 1925

- published: 09 Apr 2012

- views: 1925

- Playlist

- Chat

- Playlist

- Chat

Prestressed Concrete - Milbury Systems

- Report rights infringement

- published: 11 Oct 2010

- views: 171921

Q1. How does a prestressed precast concrete bridge beam work?

- Report rights infringement

- published: 23 Jan 2013

- views: 179791

Civil Engineering-Post tesion Concrete -construction.

- Report rights infringement

- published: 29 Jun 2016

- views: 7943

Prestressed Concrete (Introduction) PC1

- Report rights infringement

- published: 18 Jun 2013

- views: 22149

What is prestressed concrete? - Bare Essentials of Prestressed Concrete with Prof Chris Burgoyne Pt1

- Report rights infringement

- published: 21 Oct 2015

- views: 4404

Prestress Concrete Beam - Animation

- Report rights infringement

- published: 04 Apr 2016

- views: 1720

Video for prestressed concrete (with subtitle)

- Report rights infringement

- published: 04 Oct 2013

- views: 31548

Civil Engineering: Prestressed Concrete

- Report rights infringement

- published: 10 Sep 2011

- views: 144272

Prestressed Concrete (Equivalent Load Concepts) PC4

- Report rights infringement

- published: 24 Jun 2013

- views: 17505

Paul - Prestressed Concrete Technology in use

- Report rights infringement

- published: 30 Jul 2014

- views: 10276

- Playlist

- Chat

Design of Prestressed Concrete Lecture #1 2015 - Dirk Bondy

- Report rights infringement

- published: 06 Oct 2015

- views: 2360

Design of Prestressed Concrete Lecture #2 2015 - Dirk Bondy

- Report rights infringement

- published: 06 Oct 2015

- views: 1980

Precast Prestressed Concrete (9/15/2010) - Full

- Report rights infringement

- published: 10 Apr 2012

- views: 6554

Architectural & Structural Precast Prestressed Concrete (Full Video)

- Report rights infringement

- published: 10 Apr 2012

- views: 841

Prestressed Concrete (Prestress loss) PC6

- Report rights infringement

- published: 24 Jun 2013

- views: 5470

Lecture-8-Losses in Prestress

- Report rights infringement

- published: 11 Dec 2007

- views: 15323

MiBridge Seminar - Infill Prestressed Concrete Bridge Design - midas Civil

- Report rights infringement

- published: 14 May 2016

- views: 251

Precast Prestressed Concrete (Fall 2006) - Full Video

- Report rights infringement

- published: 09 Apr 2012

- views: 1925

[VIDEO] FBI's New Probe Of Clinton Emails Linked To Weiner Sexting Case

Edit WorldNews.com 28 Oct 2016FBI: New Clinton emails prompt further investigation

Edit The Associated Press 28 Oct 2016We Now Have All The New Horizons Data From Pluto

Edit IFL Science 28 Oct 2016Second Large Court Judgment This Year Against Johnson & Johnson Use Of Talc

Edit WorldNews.com 28 Oct 2016Is The Media Biased Against Trump? One Republican Delegate Thinks So

Edit WorldNews.com 28 Oct 2016Hot Property: Classical facade conceals contemporary comforts on 3rd Avenue

Edit San Francisco Chronicle 29 Oct 2016Shimla Municipal Corporation plans 20 crore waste plant

Edit The Times of India 29 Oct 201610/28/16 Road Work Report (City and County of Honolulu, HI)

Edit Public Technologies 29 Oct 2016Road/Lane Closures Week of October 31, 2016 (City of Mill Valley, CA)

Edit Public Technologies 29 Oct 2016Address by Minister Dion at a conference marking the 20th anniversary of the start of the Ottawa Process (Embassy of Canada in France)

Edit Public Technologies 29 Oct 2016Address by Minister Dion at a conference marking the 20th anniversary of the start of the Ottawa Process (Department of Foreign Affairs, Trade and Development of Canada)

Edit Public Technologies 29 Oct 2016Comment on Longtime construction executive to replace Hanabusa on HART board by Tahitigirl55

Edit Star Advertiser 29 Oct 2016Businessman featured in radio ad for Szeliga comes forward

Edit Baltimore Sun 29 Oct 2016New Oklahoma City convention center design reflects themes of earth, horizon and sky

Edit The Oklahoman 29 Oct 2016This invention saved Mike Pence's plane after it skidded off runway

Edit AOL 29 Oct 2016- 1

- 2

- 3

- 4

- 5

- Next page »