8:54

Semiconductor manufacturing process video

...

published: 10 Feb 2010

author: clee22may1975

Semiconductor manufacturing process video

8:03

Semiconductor Technology at TSMC, 2011

An up to date and current overview of semiconductor manufacturing technology from TSMC in ...

published: 27 Mar 2011

author: Andrew Shephard

Semiconductor Technology at TSMC, 2011

Semiconductor Technology at TSMC, 2011

An up to date and current overview of semiconductor manufacturing technology from TSMC in Taiwan. Nicely produced and informative if you tune-out the voice-o...- published: 27 Mar 2011

- views: 66999

- author: Andrew Shephard

10:42

Chip Manufacturing Process - Philips Factory

This video shows the detail process of making of a chip at Philips Factory....

published: 25 Aug 2010

author: professorgstatla

Chip Manufacturing Process - Philips Factory

Chip Manufacturing Process - Philips Factory

This video shows the detail process of making of a chip at Philips Factory.- published: 25 Aug 2010

- views: 21654

- author: professorgstatla

3:35

ASML - Powering the next phase of semiconductor manufacturing

To make chips smaller, smarter and cheaper, ASML lithography systems need phenomenally adv...

published: 05 Nov 2008

author: jeannotdriedonkx

ASML - Powering the next phase of semiconductor manufacturing

ASML - Powering the next phase of semiconductor manufacturing

To make chips smaller, smarter and cheaper, ASML lithography systems need phenomenally advanced mechatronic systems, lenses and software that increase the re...- published: 05 Nov 2008

- views: 46988

- author: jeannotdriedonkx

2:08

ABB's semiconductors facility in Lenzburg / Switzerland

Lenzburg is ABB's center for the production of power semiconductors, a 24-hour factory wit...

published: 12 Apr 2011

author: abb

ABB's semiconductors facility in Lenzburg / Switzerland

ABB's semiconductors facility in Lenzburg / Switzerland

Lenzburg is ABB's center for the production of power semiconductors, a 24-hour factory with two production lines that have a combined output of around 225,00...- published: 12 Apr 2011

- views: 10608

- author: abb

3:40

Semiconductor Fabrication

...

published: 04 Jul 2011

author: mbaldwin1618

Semiconductor Fabrication

4:26

What makes a semiconductor manufacturing process successful?

What makes a successful semiconductor manufacturing process? Ivor Evans tells us about th...

published: 27 Aug 2013

What makes a semiconductor manufacturing process successful?

What makes a semiconductor manufacturing process successful?

What makes a successful semiconductor manufacturing process? Ivor Evans tells us about the semiconductor industry, CSR's thorough operations process, our manufacturing partners and what it feels like ship nearly four billion chips. Disclaimer: This presentation contains certain statements (including, statements concerning plans and objectives of management for future operations or performance, or assumptions related thereto) that are 'forward looking statements' within the meaning of the United States Private Securities Litigation Reform Act of 1995 in relation to the future financial and operating performance and outlook of CSR, as well as other future events and their potential effects on CSR. These forward-looking statements can be identified by words such as 'believes', 'estimates', 'anticipates', 'expects', 'intends', 'may', 'will', 'plans', 'should' and other similar expressions, including statements relating to: expected developments in our product portfolio, expected revenues, expected annualised operating costs savings, expected future cash generation, expected future design wins and increase in market share, expected incorporation of our products in those of our customers, adoption of new technologies, the expectation of volume shipments of our products, opportunities in our industry and our ability to take advantage of those opportunities, the potential success to be derived from strategic partnerships, the potential impact of capacity constraints, the effect of our financial performance on our share price, the impact of government regulation, expected performance against adverse economic conditions, and other expectations and beliefs of our management. All forward looking statements are based upon numerous assumptions regarding CSR's business strategies and the environment in which CSR will operate and therefore involve a number of known and unknown risks, contingencies, uncertainties and other factors, many of which are beyond the control of CSR. Actual results and developments could differ materially from those expressed or implied by these forward looking statements as a result of numerous risks and uncertainties. These factors include, but are not limited to: the ability to realise the expected synergies from acquisitions in the amounts or in the timeframe anticipated, a continuing or worsening economic downturn, which could reduce demand for consumer products; risks associated with securing sufficient capacity from the third-parties that manufacture, assemble and test CSR's products and other risks relating to CSR's fabless business model; declines in the average selling prices of CSR's products; risks associated with existing or future litigation; costs associated with the development of new products in response to market demand; errors or failures in the hardware or software components of CSR's products; cancellation of existing orders or the failure to secure new orders; risks associated with acquiring and protecting intellectual property; risks relating to forecasting consumer demand for and market acceptance of CSR's products and the products that use CSR's products; increased expenses associated with new product introductions, masks, or process changes; yields that CSR's subcontractors achieve with respect to CSR's products; the cyclicality of the semiconductor industry; the potential for disruption in the supply of wafers or assembly or testing services due to changes in business conditions, natural disasters, terrorist activities, public health concerns or other factors; CSR's ability to manage past and future acquisitions; CSR's ability to protect its intellectual property; CSR's ability to attract and retain key personnel, including engineers and technical personnel; the difficulty in predicting future results; and other risks and uncertainties discussed in our latest Annual Report. Each forward looking statement speaks only as of the date hereof. CSR does not undertake to release publicly any updates or revisions to any forward looking statements contained herein, otherwise than required by law."- published: 27 Aug 2013

- views: 28

5:13

Taiwan Semiconductor Manufacturing Company (TSMC)

...

published: 29 Mar 2013

author: BSA Verafirm

Taiwan Semiconductor Manufacturing Company (TSMC)

Taiwan Semiconductor Manufacturing Company (TSMC)

- published: 29 Mar 2013

- views: 173

- author: BSA Verafirm

5:08

SEMI Europe interview June 2009 on European Semiconductor Manufacturing Competitiveness

Heinz Kundert, President of SEMI Europe, views on retaining semiconductor manufacturing in...

published: 31 Jul 2009

author: clee22may1975

SEMI Europe interview June 2009 on European Semiconductor Manufacturing Competitiveness

SEMI Europe interview June 2009 on European Semiconductor Manufacturing Competitiveness

Heinz Kundert, President of SEMI Europe, views on retaining semiconductor manufacturing in Europe. Semiconductor Equipment and Materials International (SEMI)...- published: 31 Jul 2009

- views: 1181

- author: clee22may1975

2:43

Photo-lithography Mask For Semiconductor Manufacturing

I think this mask was used to make memory chips. It almost looks like EPROM's....

published: 24 Aug 2012

author: pamperchu

Photo-lithography Mask For Semiconductor Manufacturing

Photo-lithography Mask For Semiconductor Manufacturing

I think this mask was used to make memory chips. It almost looks like EPROM's.- published: 24 Aug 2012

- views: 1516

- author: pamperchu

2:01

Product overview of the Semiconductor Manufacturing Technology business group

Meet the ZEISS Semiconductor Manufacturing Technology business group: the highlights the s...

published: 17 Jun 2013

author: CarlZeissGroup

Product overview of the Semiconductor Manufacturing Technology business group

Product overview of the Semiconductor Manufacturing Technology business group

Meet the ZEISS Semiconductor Manufacturing Technology business group: the highlights the semiconductor equipment in our portfolio. High-tech developments wit...- published: 17 Jun 2013

- views: 125

- author: CarlZeissGroup

89:46

Advanced Energy Efficiency for Process Industries and Semiconductor Manufacturing

Amory Lovins, Chairman/Chief Scientist of the Rocky Mountain Institute (RMI) speaking at h...

published: 28 Mar 2012

author: CleanGreenSingapore

Advanced Energy Efficiency for Process Industries and Semiconductor Manufacturing

Advanced Energy Efficiency for Process Industries and Semiconductor Manufacturing

Amory Lovins, Chairman/Chief Scientist of the Rocky Mountain Institute (RMI) speaking at his seminar on Advanced Energy Efficiency for Process Industries and...- published: 28 Mar 2012

- views: 116

- author: CleanGreenSingapore

0:15

Taiwanese Semiconductor Manufacturing Industry, 3Q 2013

For More Visit:

http://www.marketresearchreports.biz/analysis-details/taiwanese-semiconduc...

published: 21 Oct 2013

Taiwanese Semiconductor Manufacturing Industry, 3Q 2013

Taiwanese Semiconductor Manufacturing Industry, 3Q 2013

For More Visit: http://www.marketresearchreports.biz/analysis-details/taiwanese-semiconductor-manufacturing-industry-3q-2013 This research report presents shipment value forecast and recent quarter review of the Taiwanese semiconductor manufacturing industry. Companies surveyed in this research are those owning facilities to make MOS (Metal Oxide Semiconductor) wafers in Taiwan, including IC foundries, DRAM (Dynamic Random Access Memory) vendors, and IDM (Integrated Device Manufacture) companies. The content of this report is based on primary data obtained through interviews, and publicly available information such as corporate financial statements. Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013,Taiwanese Semiconductor Manufacturing Industry, 3Q 2013Taiwanese Semiconductor Manufacturing Industry, 3Q 2013- published: 21 Oct 2013

- views: 2

5:50

Semiconductor Fabrication Facility - Tyndall National Institute Cork Ireland.avi

Central Fabrication Facility (CFF) @ Tyndall: Brendan O'Neill, Head of the Central Fabrica...

published: 11 Oct 2011

author: Tyndallweb

Semiconductor Fabrication Facility - Tyndall National Institute Cork Ireland.avi

Semiconductor Fabrication Facility - Tyndall National Institute Cork Ireland.avi

Central Fabrication Facility (CFF) @ Tyndall: Brendan O'Neill, Head of the Central Fabrication Facility delivers an overview of the Central Fabrication Facil...- published: 11 Oct 2011

- views: 871

- author: Tyndallweb

Vimeo results:

0:38

Lam Performance - User Interface and Interaction Design

Lam Research is a globally operating semiconductor manufacturer specializing in clean room...

published: 23 Jan 2013

author: Strukt

Lam Performance - User Interface and Interaction Design

Lam Research is a globally operating semiconductor manufacturer specializing in clean room technology for silicon wafer and microchip production.

Lam Research AG in Villach, Carinthia hired us to design an analysis tool for a clear and understandable visualization of the IT-department’s key performance indices (KPIs). The interface needed to allow for constant evaluation and commenting of the collected data in real time. The resulting software concept and user interface is called Lam Performance. It is a tool that gives executives in Villach the possibility to quickly create reports on the efficiency, quality and rentabilty of their IT department and to deliver those to the headquarter in Fremont, California.

Get more information at http://strukt.com/2013/lam-performance/

Credits

Client: Lam Research AG

Project Management: Wolfgang F. Maier

Creative Direction: Gregor Hofbauer

Art Direction: Philipp Lehmann

Screen Design: Barbara Mozdyniewicz

2:37

Semiconductor wafer manufacturing

Produced this video to market a division within a semiconductor manufacturing company that...

published: 27 Oct 2010

author: Jeff Iavecchia

Semiconductor wafer manufacturing

Produced this video to market a division within a semiconductor manufacturing company that was looking to establish a new R&D; area around common engineering approaches that could be applied across an array of wafer handling tools that shared wafer handling robotics, pressurized environments, environmental controls, and monitoring and control elements. All this to achieve more cost effective engineering design solutions. Ten years later they're still going strong.

1:31

EPROM live stage clip

Eprom is known for his diverse, funky and energetic sets, which cross the lines between li...

published: 05 Apr 2010

author: overgroun

EPROM live stage clip

Eprom is known for his diverse, funky and energetic sets, which cross the lines between live remixing and manipulation of hiphop and dubstep with his own obscenely bass-heavy neurocrunk transmissions. Eprom has played alongside artists like Flying Lotus, The Glitch Mob, Skream, Lazer Sword, Kode9, Mochipet, Rustie, and many others. Eprom has worked with internationally renowned MCs and has slated multiple vinyl releases in the coming year. DJ supporters include Starkey, Jakes, Bassnectar, The Glitch Mob, Rustie, Megasoid, Zombie Disco Squad, Riton, Basement Jaxx, and BBC Radio One’s Mary Anne Hobbs.

Independent electronic artist from Vancouver, Canada, and collaborating with hip-hop group Low pros in Toronto Canada, while containing several different styles in his music many of his remixes make appreciable use chiptune style sound

Affiliations: Surefire, Black Acre, Cloak x Dagger

An EPROM (rarely EROM), or erasable programmable read only memory, is a type of memory chip that retains its data when its power supply is switched off. In other words, it is non-volatile. It is an array of floating-gate transistors individually programmed by an electronic device that supplies higher voltages than those normally used in digital circuits. Once programmed, an EPROM can be erased by exposing it to strong ultraviolet light from a mercury-vapor light source. EPROMs are easily recognizable by the transparent fused quartz window in the top of the package, through which the silicon chip is visible, and which permits exposure to UV light during erasing.

Development of the EPROM memory cell started with investigation of faulty integrated circuits where the gate connections of transistors had broken. Stored charge on these isolated gates changed their properties. The EPROM was invented by Dov Frohman of Intel in 1971, who was awarded US patent 3660819 in 1972.

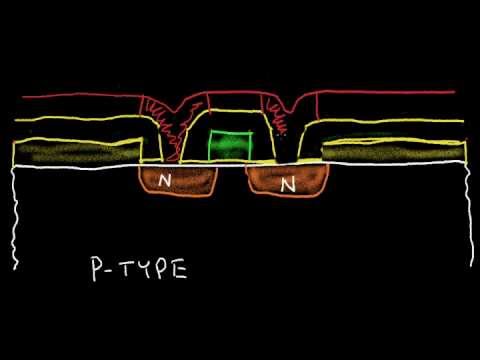

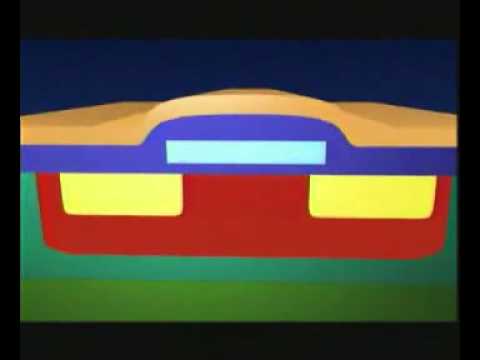

A cross-section of a floating-gate transistor

Each storage location of an EPROM consists of a single field-effect transistor. Each field-effect transistor consists of a channel in the semiconductor body of the device. Source and drain contacts are made to regions at the end of the channel. An insulating layer of oxide is grown over the channel, then a conductive (silicon or aluminum) gate electrode is deposited, and a further thick layer of oxide is deposited over the gate electrode. The floating gate electrode has no connections to other parts of the integrated circuit and is completely insulated by the surrounding layers of oxide. A control gate electrode is deposited and further oxide covers it.

To retrieve data from the EPROM, the address represented by the values at the address pins of the EPROM is decoded and used to connect one word (usually an 8-bit byte) of storage to the output buffer amplifiers. Each bit of the word is a 1 or 0, depending on the storage transistor being switched on or off, conducting or non-conducting.

The switching state of the field-effect transistor is controlled by the voltage on the control gate of the transistor. Presence of a voltage on this gate creates a conductive channel in the transistor, switching it on. In effect, the stored charge on the floating gate allows the threshold voltage of the transistor to be programmed.

Storing data in the memory requires selecting a given address and applying a higher voltage to the transistors. This creates an avalanche discharge of electrons, which have enough energy to pass through the insulating oxide layer and accumulate on the gate electrode. When the high voltage is removed, the electrons are trapped on the electrode. Because of the high insulation value of the silicon oxide surrounding the gate, the stored charge cannot readily leak away and the data can be retained for decades.

Unlike EEPROMs, the programming process is not electrically reversible. To erase the data stored in the array of transistors, ultraviolet light is directed onto the die. Photons of the UV light cause ionization within the silicon oxide, which allow the stored charge on the floating gate to dissipate. Since the whole memory array is exposed, all the memory is erased at the same time. The process takes several minutes for UV lamps of convenient sizes; sunlight would erase a chip in weeks, and indoor fluorescent lighting over several years. Generally the EPROMs must be removed from equipment to be erased, since it's not usually practical to build in a UV lamp to erase parts in-circuit.

As the quartz window is expensive to make, OTP (one-time programmable) chips were introduced; here, the die is mounted in an opaque package so it cannot be erased after programming - this also eliminates the need to test the erase function, further reducing cost. OTP versions of both EPROMs and EPROM-based microcontrollers are manufactured. However, OTP EPROM (whether separate or part of a larger chip) is being increasingly replaced by EEPROM for small amounts where the cell cost isn't too important and flash for larger amounts

49:50

StartupCircle Presents: Bryan Pate, ElliptiGo, Inc.

Bryan Pate, Co-Founder and Co-President of ElliptiGO, Inc.

Bryan earned a Bachelor's of S...

published: 17 Apr 2012

author: StartupCircle

StartupCircle Presents: Bryan Pate, ElliptiGo, Inc.

Bryan Pate, Co-Founder and Co-President of ElliptiGO, Inc.

Bryan earned a Bachelor's of Science degree in Earth Systems from Stanford University in 1995. Upon graduation, he joined the U.S. Marine Corps as a 2nd Lieutenant.

As a Marine Officer, Bryan led a platoon of Scout Snipers during a deployment to the Persian Gulf and also served as an intelligence officer on an admiral's staff.

After the Marines, Bryan accepted a strategic marketing position at semiconductor equipment manufacturer Palomar Technologies, Inc. While at Palomar, Bryan was promoted to the position of Product Marketing Manager responsible for new products. In that role he helped lead two new product development efforts at Palomar.

In 2002, Bryan left Palomar to attend Columbia Law School. After graduation he completed a one year federal court clerkship and then joined McKinsey & Company, a management consulting firm.

In 2005, during his federal court clerkship, Bryan approached Brent Teal, a friend and former Palomar co-worker, with the idea for the ElliptiGO. In 2008, after three years of working with Brent on designing, developing, and testing prototypes, Bryan left McKinsey to work full-time on the ElliptiGO project. Bryan and Brent co-founded ElliptiGO Inc. at the end of 2008 to commercialize the world's first elliptical bicycle.

As a company co-founder and co-president he has taken the lead on corporate strategy, marketing, and fundraising.

Youtube results:

3:38

The FinFet Semiconductor Process

Threshold Systems provides consulting services to semiconductor manufacturers, semiconduct...

published: 07 Aug 2012

author: ThresholdSystems

The FinFet Semiconductor Process

The FinFet Semiconductor Process

Threshold Systems provides consulting services to semiconductor manufacturers, semiconductor equipment and chemical suppliers, as well as high-tech start-up ...- published: 07 Aug 2012

- views: 1954

- author: ThresholdSystems

100:38

Lecture 18: Intro to Semiconductor Physics, PN Junctions, Chip Manufacturing

Lecture 18: Tradeoffs in Digital Circuits (Power, Speed, Cost), Diodes http://www-inst.eec...

published: 26 Aug 2010

author: UCBerkeley

Lecture 18: Intro to Semiconductor Physics, PN Junctions, Chip Manufacturing

Lecture 18: Intro to Semiconductor Physics, PN Junctions, Chip Manufacturing

Lecture 18: Tradeoffs in Digital Circuits (Power, Speed, Cost), Diodes http://www-inst.eecs.berkeley.edu/~ee40/su10/lectures/lec18 Introduction to Microelect...- published: 26 Aug 2010

- views: 18102

- author: UCBerkeley

7:38

Fab 32 - Intel's first high-volume 45nm chip factory

Fab 32 is Intel's latest environmentally-friendly factory that will manufacture tens of mi...

published: 19 Jan 2009

author: Rasanga Perera

Fab 32 - Intel's first high-volume 45nm chip factory

Fab 32 - Intel's first high-volume 45nm chip factory

Fab 32 is Intel's latest environmentally-friendly factory that will manufacture tens of millions of the most energy-efficient processors the company has ever...- published: 19 Jan 2009

- views: 56667

- author: Rasanga Perera

2:19

Taiwan Semiconductor Manufacturing Corporation: Consiglieri Steering Committee | 新竹市

謝謝 - 陳盈吉 Tel. +886 928 178 387 Head Office : +886 4 2203 2553 edu.service@msa.hinet.net Ev...

published: 01 Apr 2012

Taiwan Semiconductor Manufacturing Corporation: Consiglieri Steering Committee | 新竹市

Taiwan Semiconductor Manufacturing Corporation: Consiglieri Steering Committee | 新竹市

謝謝 - 陳盈吉 Tel. +886 928 178 387 Head Office : +886 4 2203 2553 edu.service@msa.hinet.net EverDependUp Co., Ltd. / Chen En Ji A.V.&V.A.; Daniloff PR : Pamir Law...- published: 01 Apr 2012

- views: 136

- author: KOMATSU CEO Tetsuji Ohashi - Osaka Plant